The Story:

My good friend, Billy Holder, and I created what we called 'The Device' some time ago. It was a successful over complication of a beer delivery funnel, also known as a 'beer bong'. Sadly Billy moved out, and there was a deep loss felt from 'The Device' and such the incarnation of 'The Device 2.0®'. This was to be the biggest, most over complicated, most over engineered beer bong ever created. In fact it was to be such a spectacle it was to have it's own documentry website, and thus you have read this, and it has been done.

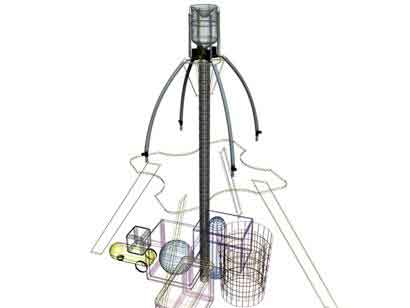

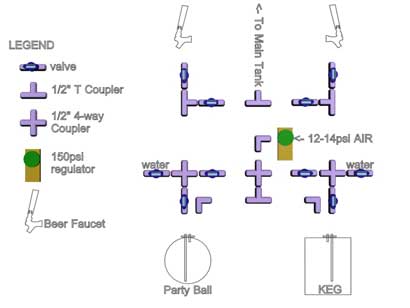

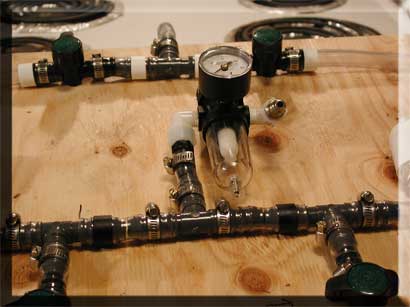

The basic idea, simultaneously tap two beer sources being either a sankey Keg, or a 5-gallon party ball, push it with a replenishing air compressor to either a faucet, or up to a 4-gallon upper holding tank with four hoses leading off into four mouths racing to finish their hose.

Specs:

Media type: Keg / Partyball / Water / Air

PSI: Tank-120/First drop-30/BeerSwitch drop-12-14

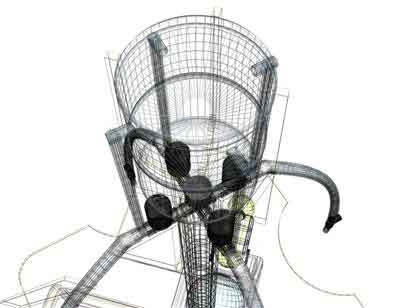

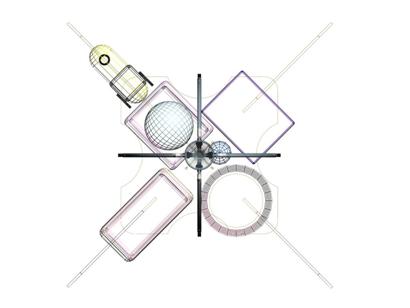

Upper Tank: 4-gallon capacity with hoses / Activly intercooled via radiator and refidgerator based resevoir.

BeerSwitch: Able to redirect water, air, or beer from two sources into two faucets, up to the main tank, or all three at the same time.

(2/8/04) - Derek, my new roommate, and I have assembled the top holding tank unit for 'The Device 2.0®' and I have the next two days off, wherein I should be able to bring this project to 75% completion.

I intend to complete the BeerSwitch® valved media control panel with the exception of the food-grade quick disconnects. After this is complete I will engineer connections to - and modify a small dorm refridgerator into an intercooler for the main holding tank. Then, I will construct the massive supporting frame for this might beast from a half sheet of 4'x8' sanded plywood, and 2x6 45° legs. This will be a skirt which will center a 4" ABS pipe for vertical support of the upper holding tank.

(2/11/04) - I have reached my goal for 75% completion. The BeerSwitch® is completed! The quick disconnects are on their way from US plastics. The top holding tank has the intercooler installed, the initial refridgerator modification has taken place, and everything is plumbed, tested, and not leaking. (except some points on the BeerSwitch®, which will be resolved shortly with a few more hose clamps. With any luck 'The Device 2.0' should reach 95% completion if not completly done by next tuesday. Check back soon for updated pics/info!

(2/12/04) - I had a flat tire yesterday, and ended up having to buy another tire. So that threw off my materials acquisition for last night. So instead We went to the Pressbox bar-boring. Came home and decided to alpha test the upper holding tank. I've always liked watching the discovery channel, and recently there have been some cool series' like Monster Garage, and Mythbusters. Derek and I were discussing yesterday how the concept of this project feels like something straight out of monster garage, and building it feels like a real-life Mythbusters episode. So very cool.

We didn't get a shot of it, but I loaded 2 up before hitting it. From the valve to the slice gate as best we can measure it holds damn near 2x 12oz cans of beer in the hose.

Looking at these pictures I think I'll make an indoor stand for it as well, since this top portion is completly modular.

(2/13/04) - Derek and I threw together the intercooler lower cooling unit last night. It didn't work out as good as I thought it would had, so we are going to make some modifications later. I'm gonna work from 3pm to 6am today, so that will hopefully get some good OT $$ to complete this project =) Pictures as follows:

(2/18/04) - ! AS PLANNED WE ARE DONE ! All sub-modules of this device are complete. There is still some testing/tweaking/after-the-fact modification/etc to bring the device to the most optimum level, but as is, IT'S READY TO ROCK! I'll let the pictures do the talk'n now->

I have submitted this device as 'The largest Beer funnel in the world' to Guinness World Records, and is currently under review. I am also awaiting a call from the Idaho Alcohol Beverage Control to ascertain this device's legality.

Provided this device is legal for personal use on private property ;-) Action shots will be soon to follow, stay tuned!

(2/20/04) -It would appear as thought this device is in compliance with Idaho alcohol laws

Special Thanks:

Floyd Lilly Co (Specialty hose, valve, & pump)

PipeCo (Sprinkler systems)

Berta Bowersock of US plastics tech support

Extra special thanks to Jason Stevens of Watkins dist. (Budweiser) I got hooked up, thanks man!

For even more super-mega awesome fun, check out -

The Greeks invented the 'Beer Funnel', hmm...